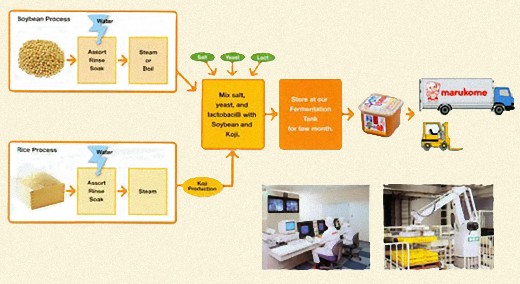

At Marukome's immaculate, cutting-edge factory facilities, Miso is prepared by mixing steamed soybeans with koji yeast and salt, then allowing the mixture to ferment for several months. Marukome uses the most modern preparation systems within a state-of-the-art production line. Rice- and soybean-steaming systems, as well as 120-ton fermentation tanks, are all part of the production line.

Marukome uses only non-GMO (Genetically Modified Organism) soybeans to produce high-quality Miso at its factories. Soybeans are rinsed and soaked within large tanks for several hours so that the soybeans become soft. Then, they are either steamed or boiled.

Click to Enlarge Factory Picture

Rice is sorted, rinsed, and soaked for several hours in a large tank. Then, after steaming, koji bacillus is introduced, and incubated overnight to produce the variety of yeast necessary in making the best Miso.